Increasingly, participants in supply chains are digitizing their operations and looking to new technologies for the future of continuous optimization. With so many different components in motion within the supply chain, real-time data sharing is integral for ports to maintain big-picture vision while keeping an eye on day-to-day movements to identify where problems are occurring. From containers to truck movement, real-time data sharing provides insights that benefit supply chain operations.

Ports are Investing in Real-Time Data Sharing

One example of real-time data sharing is Port Community Systems (PCS). PCS are open, electronic platforms that allow different organizations and companies to connect their databases and share data with each other. This means that shippers, customs brokers, warehouse managers, government agencies, terminals, and everyone else involved can share their data to keep the supply chain running smoothly and its stakeholders informed.

At a governmental level, data sharing examples include the US government’s FLOW initiative. Launched in March 2022, the Freight Logistics Optimization Works (FLOW) is an information-sharing initiative to pilot key freight information exchange between parts of the goods movement supply chain. In April 2023, five of California’s largest ports signed a pledge to build a data-sharing system with real-time interoperability with a common goal of supporting improved freight system resilience, goods movement efficiency, emissions reduction, and economic competitiveness.

In addition to Port Community Systems, numerous, nimble real time data-sharing initiatives have been implemented around the world to improve the efficiency, transparency, and resiliency of the supply chains in anything from vessels, cargoes to landside mobility.

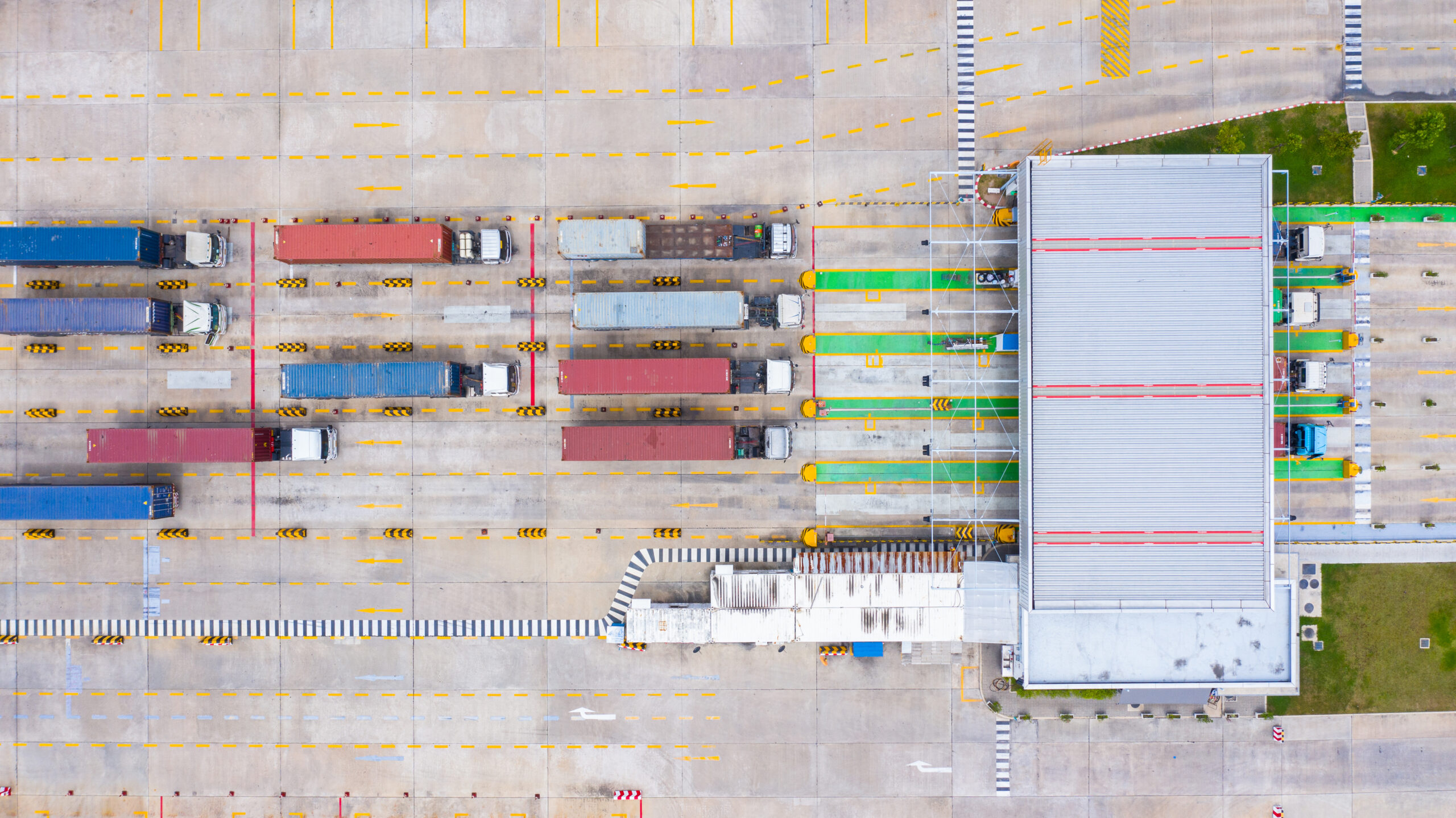

For example, in Canada, the Port of Montréal implemented Trucking PORTal, a smart interface that informs drivers and carriers about traffic volume in real time. Also in Canada, the Port of Trois-Rivières, Québec, collected real-time data to gain visibility into truck turn time and its inside-the-yard movements. The port installed SMATS’ Bluetooth sensors, paired with iNode software to track truck routes, idle times, and travel times in between stops inside the yard, such as from the port gates to the scales. The project is a cornerstone of the port’s data collection and sharing initiatives that will span all aspects of its operations.

Collecting Truck Data is Easier Than it Seems

While many supply chain executives are on board with the importance of data sharing, they recognize that the lack of data access can get in the way. When it comes to truck data, however, the good news is that collecting data may be easier than it seems.

According to American Trucking Association, trucks move 72.6 percent of America’s freight by weight. Since 99 per cent of overseas trade arrives at ports first in the United States, much of this freight is transported by trucks.

There are four primary technologies for collecting the raw data on truck identification, time, and location within and around ports and terminals. First, by tapping into Bluetooth or Wi-Fi signals emitted by drivers’ smart devices or via deployed tags. Second, by tapping into Global Positioning System (GPS) data collected via devices deployed in trucks, such as location apps or fleet trackers. Third, via Automated License Plate Recognition (ALPR) cameras which pair license plate information with truck’s time and location data. Finally, by Radio Frequency Identification (RFID) tags and readers which collect truck identification and location information when they are within a certain range. Each of these methods comes with advantages and disadvantages which port leaders must weigh carefully against their data sharing objectives and existing technology infrastructure.

Turning Data into Analytics and Insights

Data Quality is Paramount

Quality data is important but assessing quality is not always easy. One of the key indicators of quality data is sample size. Sample size does not need to be 100 percent to indicate quality data, but it does have to be representative of the reality. Factors that impact sample size, or data capture rate, include weather, visibility, tag adoption rate, signal strength and range, and more. Data collection methods that achieve a high sample size representative of total traffic, such as SMATS’ Bluetooth sensors, offer quality data that can be trusted to produce reliable metrics and insights.

Another key attribute to data quality is immediacy. Timely operational adjustments can only be achieved based on real-time or near-real-time data. This data can be hard to get because data sources such as GPS can experience delays for up to several days.

Another factor to consider is compatibility, i.e., is there any application in place that can translate it to your existing systems, such as Port Community Systems (PCS) Terminal Operating Systems (TOS), Truck Appointment Systems (TAS), Automatic Identification Systems (AIS), and Variable Message Signs (VMS). Applications such as SMATS’ iNode are agnostic of data sources and can be linked to any of the systems above via API.

Building Greener Ports

Speeding up the Supply Chain

As ports become more digital, there is a need for real-time data to allow for proactive assessment and decision-making. According to a research study in the Maritime Transport Research journal, landside congestion can have negative effects on the supply chain by creating delays, creating uncertainty for logistics service providers, raising costs for the supply chain as a whole, and making ports less competitive in the long run. While solving landside congestion is only one part of what makes a port competitive, it plays a critical role in the supply chain. Reducing landside congestion helps mitigate uncertainty for stakeholders, reduces costs, keeps communities happier, and makes the port stronger and more competitive.

Real-time data can help your port and terminals reduce landside congestion and offer critical insight into how trucks are moving through your port. Real-time data provides valuable metrics, reduces air pollution and greenhouse gas emissions, and improves operations and the competitiveness of your port.

With so many different components in motion within the supply chain, real-time data sharing is integral for ports to maintain big-picture vision while keeping an eye on day-to-day movements to identify where problems are occurring.